» Clean, simple design

» High efficiency – time saved during inspection, cleaning and maintenance

» Operator friendly – no tools required for stripping down and cleaning

» Easy access to oversize end door for opening in seconds

» Easily removable sifter screen for inspection and cleaning

» No leakage or contamination at the oversize end

» 360° in-place rotation of sifting screen for inspection of the complete screen without removal from the machine.

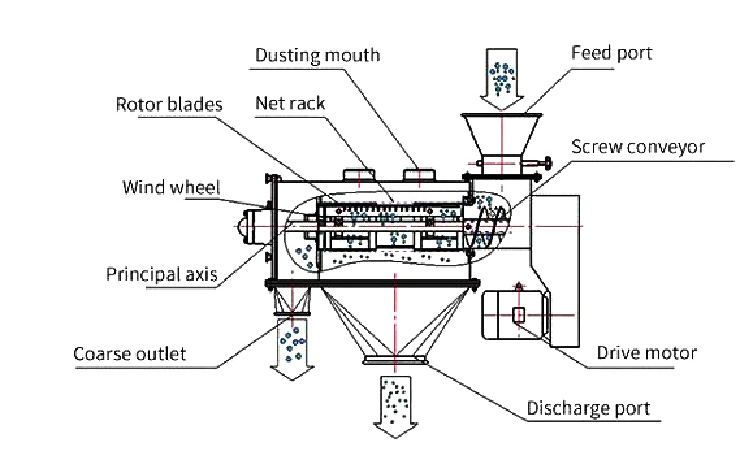

» Material is fed into the sifter inlet and accelerated by an auger.

» The auger moves the material into the cylindrical sifting chamber where it is picked up by the rotating paddle/blade assembly and propelled against the sieve screen.

» The blades on the paddle assembly are set in a helical configuration to move the material along the entire length of the sieve screen at the optimum sieving rate for any respective applications.

» The fine material passes through the screen and is collected at the main sifter outlet.

» The oversized and/or foreign material is moved to the end of the sifter chamber and, after passing around the end baffle, is discharged via a separate smaller outlet.

Contact: Sunny Lou

Phone: 0086-15136730565

Tel: 0086-373-5132620

Email: zhonghaomachinery@hotmail.com

Whatsapp: 0086-15136730565

Add: Weiye central park,Hongqi district,Xinxiang city,Henan province,China